What is DCIM? What are the uses of DCIM in Data Centers?

DCIM is an Industrial IoT application for Data Centers. It combines centralized monitoring over an IP network of connected machines with energy analytics and Data Center KPIs like Power Usage Effectiveness (PUE).

Data Centers have Racks/Cabinets to store their servers. They often use Uninterruptible Power Supply (UPS) and Power Distribution Units (PDUs). It consumes vast volumes of power to run and connect to servers, networks and facility equipment. To maintain a certain level of safety and security: electric load balancing at different power sockets and racks, keeping a stable optimal temperature to prevent overheating, regulating air quality, pressure and cooling equipment is necessary. This regulation, monitoring and measuring efficiency is done in data centers through Data Center Infrastructure Management or DCIM.DCIM devices can be used to observe data center components like power dispersion components, servers, capacity equipment and organization hardware.

The functions and elements of DCIM emulsions vary, but the power consumption and regulatory control can reduce costs. Using DCIM is also very profitable for your business because of the following:

- Uncover cost saving prospects,

- Lower risks

- Evaluate transformation impact

- Enhance performance and productivity

- Systematize and enhance capacity planning and projecting,

- Support IT business goals

- Lower power utilization

- Enhance asset consumption

- Supervise and enhance availability

- Reduction of equipment supply/discarding obstacles

- Upgrade overall IT service delivery.

For more on the subject please click on the link below:

Read More

Why would Infrastructure IT Managers need DCIM?

Infrastructure IT managers have to cater to the needs of Data Centers to keep the IT equipments or the facility up and running. Some of the Data Center Management Problems would include:

- Management of Multiple devices, networks, servers and their repair or upgrading processes.

- Maintenance of SLAs in critical areas where data storage, data rates and data access communications are available.

- Monitoring shortcomings due to power imbalance caused by change of systems,

- Obsolete equipment and inability to maintain infrastructure.

- Managing Data Center expenses and budgets. Resources are purchased at the best cost:

- Whether it is electrical capacity or energy costs due to air-conditioning which form a huge percentage of investment.

- Accelerate implementation of new services while optimizing space & workload and also ensuring stability of temperature, air pressure, air quality.

DCIM devices can be used to observe data center components like power dispersion components, servers, capacity equipment and organization hardware.

DCIM ensures safety and security of Data Centers in the following ways:

- Providing valuable information to the Infrastructure IT manager regarding the efficiency of all IT as well as facility equipments.

- Through quality control and checks (and answering questions like: What is gauge? What is excellent? What is atypical? What is awful?)

- Guaranteeing uptime.

- Frameworks Discovery or Network gadget disclosure can be used by Data center administrators to take stock of all IT gadgets in and around the office. Associated estimation instruments for power conveyance and air quality should likewise be represented and thought of.

- Observing and Reporting-Once one has an exact office stock, Data Center

- Equipment checking should be utilized to quantify execution pointers but it has its down-sides. DCIM reports actual occurrences and episodes that permit a user to figure out the commotion and recognizes the requirements.

- Representation -Infrastructure and organization planning apparatuses can be

- Utilized to hoist the presentation of Data Center supervisors by giving a natural comprehension of the office and stream of data.

For more on the subject please click on the link below:

Read More

What is BMS & its Control Functions? How is DCIM different from BMS?

A Building Management System (BMS), is a computer-based control system that monitors and regulates the mechanical and electrical equipment in a building, including ventilation, lighting, power systems, fire systems and security systems. In data centers, many alarms are connected to theBMS and will notify the NOC (Network Operations Center) in case of an alarm. Usually, the BMS monitors and controls a myriad of smart building devices such as heating and cooling equipment, video and access control, fire, sprinklers and water systems, sensors, lighting and electric power management and more.

The BMS can also supervise and report on the variables and changes associated with the data the BMS collects about said devices. A properly configured BMS can manage and supervise variable conditions, alarms, provide current status and historical information of building elements, help with diagnostics, interfacing between smart applications used in buildings, etc

Some of the BMS like Control Functions also provided by DCIM could be:

- Fuel Automation Management

- Air Quality Control

- Air Handling Unit (AHU) Control

- iPDU Control

The role of DCIM and BMS seems more complementary than mutually exclusive, but on certain occasions DCIM could offer a lot more than traditional BMS. Here are some key differences between DCIM and BMS:

Predictive analysis is a domain for DCIM. Although BMS is highly effective in monitoring major parameters of major systems, and raises alarms if something fails but predictive analysis is not the job for BMS.

Failure of Air-quality or Air-conditioning in a building might cause temporary discomfort but failure of Air Quality Control system or Air-Conditioning could be extremely hazardous for a Data Center. Unlike BMS, a DCIM can provide trend information for proper maintenance before something critical fails. Prediction in a Machine Learning application requires processing of huge volumes of data and the coming up with trends. BMS is not meant for processing large data volume.

DCIM is a one stop solution for managing all data center problems. Certain arenas require the expertise of DCIM software. BMS does have its limitations. DCIM can do a lot more than just providing control or regulatory functions:

- Electrical phase balancing: The output of every large uninterruptible power supply (UPS) and the branch circuit distribution to many data center racks, is three-phase. To calculate the maximum capacity from each circuit and the UPS, equalize the current draws on each phase. All UPS systems and many power distribution units (iPDU’s, CDUs and so on) have built-in monitoring, but it’s inefficient to run from cabinet-to-cabinet and device-to-device to balance power.

- “Intelligent” PDUs which comes along with IP-addressable interfaces the DCIM can track the power draws on each phase in each cabinet, as well as at each juncture in the power chain. Users can calculate a balanced scheme before making actual power changes in cabinets whereas BMS tracks only the incoming power to the UPS, which is not enough to calculate the maximum capacity from each circuit and the UPS.

- Rack and cabinet temperature/humidity monitoring: The BMS monitors some representative point in the room and generates alarms if this point hits a value beyond the threshold limit but DCIM does it full scale. Temperatures vary significantly from the top to bottom of a cabinet and across the breadth of a facility. With higher inlet temperatures and denser cabinets becoming the norm, comprehensive temperature information matters when deciding where to install a new piece of equipment, or during an air conditioner maintenance or failure period. “Intelligent” PDUs have temperature and humidity probe accessories to monitor critical points on cabinets& the room while even a mini scale DCIM can process this additional load information into useful data.

- Asset and Inventory Control: DCIM always tracks and monitors asset location, asset ownership data and relation between device/equipment (assets) but the newest advancement in this direction are the radio frequency identification tags. DCIM tracks assets using these radio tags which is helpful in large facilities where there is a constant need to add or remove or repair assets.

For more on the subject please click on the link below:

Read More

What is PUE? Can DCIM measure multilevel PUE in Data Centers?

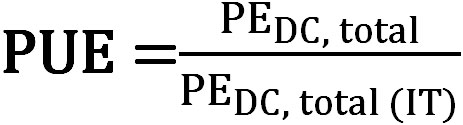

PUE or Power Usage Effectiveness is the most well-known key performance indicator used in Data Center industry to quantify the efficient use of energy in form of electricity. PUE is defined as ratio of the Data Center total energy consumption to information technology equipment energy consumption, calculated measured or assessed across the same period. Due to the heterogeneity of Data Center facilities, it is not smart to compare them directly instead we should observe their trends in an individual facility over time to determine effects of different design or operational decision within a facility.

PUE is a function of multi-variables but primarily .it is calculated as total primary energy consumed by the Data Center [(PE) of DC (total)] divided by the total primary energy delivered to the IT Equipment[(PE) of DC (IT)].

PUE is a unit-less metric which indicates the overall power to racks (Total) vs. power to support (IT) equipment. While meters at the utility level provides the total power reading, measurements across Power Distribution Units (PDUs) provides power across IT equipment. It is an impossible but ideal scenario for PUE to be 1. But for most practical purposes the PUE in a well-functioning Data Center is 1.59.A value closer to 1.59 or 1 is considered optimal. PUE can be minimised by replacing inefficient hardware, improving cooling system and through increased virtualisation of the servers.

The Green Grid defines three levels of PUE Level 1 which is the Basic, Level 2 or the Intermediate and Level 3 or Advanced. The various levels of PUE are needed to measure Power Distribution Losses. The sophistication of the UPS and PDUs as well as the power measuring tools/meters determine the Level or category of the PUE being measured. The variable that changes with different levels of PUE is the IT power consumption and the levels at which its value is measured.

- For level 1 or Basic PUE: IT Power is measured at the UPS output (At 1st Level) in Kilo-Watt Hour (KWhr). The UPS output gives the ground level IT power consumption.

- Level 2 or the Intermediate PUE: IT power is measured at PDU level (At 2nd level) in Kilo-Watt Hour (KWhr). PDUs or Power Distribution Units can be placed on floors or they could be power strips on Racks or walls. For level 2 we measure the PDU output of floor PDU as IT power.

- Level 3 or Advanced PUE: IT power is measured at rack PDU level (At 3rd level) in Kilo-Watt Hour (KWhr). For level 3 we measure the PDU output from power strips on Racks or walls as IT power. The advanced version of a Rack PDU is the iPDU at power slot level which can expose the data on SNMP.

For more on the subject please click on the link below:

Read More

Why is Air-Quality monitoring in Data Centers is important?

Airflow management is a vital aspect of data center thermal management. Air quality is a multivariant function but a sudden drop in air pressure could influence on the computer room air conditioning (CRAC) unit’s performance. Movement of hot air, cold air, contamination of particulate matter in the air could highly influence thermal and pressure balance on the devices which is very critical for their optimal function and to enhance their utility or longevity. If device/equipments within the facility last longer we could subsequently reduce capital expenses.

High Humidity and Poor Indoor Air-Quality can be disastrous for Data Centers: Unchecked concentrations of humidity, temperature, and various chemicals can lead to serious consequences like Data Center Corrosion. Data centers in urban locations have reported failures of servers and hard disk drives caused by sulphur corrosion. Monitoring of Data centre’s Indoor Air Quality is important, in order to keep a check on corrosion effect on the data center:

- Air Filtration Is a Must: Any company that owns a data center must act pre-emptively to negate the effects of poor indoor air quality with an effective air filtration system.

- Active Air Quality monitoring through BMS/ DCIM is Critical: Systems that provide real-time monitoring are crucial to ensure that the air filtration devices are working at optimal efficiency. Filters can clean the air inside data centers

- Air Quality Sensors: Acidic gases are typically the most harmful and require better monitoring. Small concentrations of Acidic Gases such as hydrogen sulphide (H2S), Sulphur Oxides, Chlorine and Nitrogen Oxides in the air can result in huge losses for IT and Data Centers. Due to the presence of SO2, acidification and eutrophication (causing the growth of algae) can take place inside the data center, which can inevitably harm IT equipment. In data centers, presence of SO2 at higher levels will attack certain types of metals of electronic circuit boards eventually resulting in corrosion. In worst cases scenarios, component or circuit failures result in unexpected downtime for IT devices leading to losses and high maintenance costs.

Read More

What are Container Data Centers? Do Container Data Centers require DCIM like capabilities?

The Container Data Centers also known as the Modular Data Centers are portable, energy efficient and fully functional data centers that consume as much as 50% of the power as a regular data center and come with physical infrastructure including power and cooling systems and remote monitoring. These data centers can be shipped and deployed into any environment just as containers and hence the name. They are highly mobile in nature and serve great purposes for enterprises that do not have access to real estate or large facilities. They are highly popular in defence sectors as well. The second characteristic is Modularity. Built with high degree of standardized components for power, cooling, safety and access security, the MDC can be shipped as single rack, single row or multiple rows. Modules of racks and rows can be added as computing needs grow. Lastly, all the critical infrastructure components (power, cooling, safety, access security), come as a Converged Unit for a Rack or a Row of Racks, unlike the discrete elements of a traditional data center. After over a decade, and the rise of IoT, the value proposition of MDC has evolved to a rapid deployment of Edge Data Center.

The industry is rapidly embracing a modular approach to data center infrastructure. The expectation is this trend would accelerate as customers are moving their principal computing to either Cloud infrastructures with satellite nodes or deploying smaller – usually multiple and distributed – captive Modular Data Centers (MDCs). The market growth of MDCs is accelerating with greater adoption of Internet of Things (IoT) and Edge Computing (satellite nodes) is becoming a necessity.

The reason why Container Data Centers require DCIM like capabilities:

The MDCs come with all the necessary modules except the monitoring piece of the converged infrastructure. Even in MDC, one needs to ensure that actual power load on rack is within rated capacity, the heat levels are within safety limits and there is appropriate load balancing within the redundant UPS units. For this purpose, GFS Crane has introduced the Rack Management System

Having full-fledged DCIM for a single or dual rack Modular Data Center would be an overkill for monitoring the critical infrastructure components of the MDC. Hence, a purpose-built Rack Management System is designed for them, which can be viewed as subset of a fuller DCIM. The Rack Management System monitors and sends alerts for the critical infrastructure devices shipped with the MDC: UPS, Cooling Unit, iPDUs, temp/humidity sensors, fire alarm system, water leak detection probe, CCTV and Access Control System. As standardization and converged infrastructure are key attributes of MDC, most MDC manufacturers are including and shipping Rack Management System as part of the converged infrastructure of their Modular Data Center offering.

GFS Crane Rack Management is a subset of GFS Crane DCIM, purpose-built for each vendor’s MDC offering. It is shipped with device OIDs in the seed data base, making it 100% plug-and-play. The Rack Management System monitors and sends alerts for the critical infrastructure devices shipped with the MDC: UPS, Cooling Unit, iPDUs, temp/humidity sensors, fire alarm system, water leak detection probe, CCTV and Access Control System. Our MDC manufacturing partners include GFS Crane Rack Management as part of their converged infrastructure offering-installed, pre-configured and shipped from their factory.

It is important to note that the Rack Management for Container Data Centers are sold to the Manufacturers of such data centers. It is an OEM only product. It gets installed in the factories prior to being sold as modular data centers. This is a plug and play option where GFS Crane Rack Management is pre-installed by Manufacturers and is ready to use once it reaches the customer.

For more on the subject please click on the link below:

Read More

Can DCIM be provided as a service for Micro or Edge Data Centers?

Micro or Edge Data centers are also referred to as the server halls or the server rooms are not necessarily Container (or Modular) Data Centers that are manufactured in Factories under standard operating conditions or guidelines. They maybe but not necessarily. So, Rack Management Software cannot cater to their needs. For Micro Data centers/server halls DCIM could be deployed in Private clouds to provide Monitoring as a Service and Asset Management as a Service.

GFS Crane Cloud for Device Monitoring as a Hosted Service

- Hosted environment. Multi-tenancy to support multiple customers & organizations with data security

- Sends critical alerts to designated staff via email & SMS alerts

- Collects status, health and performance data from different device categories & different OEMs

- Displays monitored data, alerts and KPIs on a customizable dashboard.

- Provides analysis that helps reduce failure rates. improve efficiency and performance of the Devices

GFS Crane Cloud for Asset Management as a Hosted Service

- Asset Discovery via SNMP. Non-SNMP asset details uploaded from spreadsheets

- Maps static attributes of assets from a central OEM Library to create a consolidated asset inventory

- Maps critical relationships and dependencies among assets

- Maps asset ownership hierarchy and escalation matrix

- Maintenance Management schedule; Sends alerts before due dates

- Based on Replacement Policy, identifies refresh options for an equipment from OEM Library

- Provides Visual display of Racks with U-space occupancy, including device images obtained from OEM Library

A relevant read on Asset Management & Device Monitoring for Small Data Centers:

Read More

What benefits can Colocation Data Centers derive from DCIM?

Colocation Data Centers are huge facilities. Often times, they require installation of new equipments and keeping track of large volumes of old IT equipment: their location and longevity. Equipments last longer with environment (air quality, temperature, pressure) monitoring and regulation, optimization of power and cooling resources (also known as Capacity Planning) and up-to-date tracking and management of assets. Colocation operators lack information when they need to deploy new equipments at optimal time and capacity say PDUs and Rack PDUs.

Certain questions that might arise in this scenario could be:

- How will the installation of a new gadget impact the redundancy and uptime?

- What is the longevity of my current assets if the environment is optimized and when will I need additional back-up equipment?

As more and more IT equipment is added to a colocation facility the actual rack density of the data center or room can exceed the design limits. The resulting stresses on the power and cooling systems can cause downtime from overloads, overheating, and loss of redundancy.

DCIM helps a Colocation Data Center in:

- Resource Tracking and management and planning capabilities.

- Providing customers with secure private portals to work in a multi-tenant environment.

- Offering an Asset Inventory which displays current location of Assets and their Ownership.

- Providing Predictive Analysis on maintenance and longevity of Devices.

- Providing Environmental reports to enhance device life.

- An OEM Library

- 2D and 3D visualization of space and resources. Layouts of DC Floor and Racks with other facility devices for multiple floors or halls or zones as well as Thermal Maps.

- Uptime Reports for monitored Devices

- Individual billing of power and space for each tenant monitored.

- Offering DCIM as a Service with Multi Customer Logins

- Generating alerts when tenant exceeds load limits.

- Generating alerts when SLA parameters are exceeding threshold limits.

- Calculating UPS Load in Percentage and Capacity in Kilo Volt Ampere.

DCIM portals for customers as a value-added service:

- Tenants can access their own infrastructure within a multi-level platform without compromising their security.

- Reports and alarms can be configured for specific parameters based on individual customers.

- Load balancing and capacity management of IT equipment, to prevent stranded capacity or vertical white space and hence reduce operational expenditure.

A relevant read on Asset Management and Capacity Planning:

Asset relationship in dcim Capacity planning in data center

What is Stranded Capacity? How does DCIM measure Stranded Capacities?

Commonly the DCIM represents the resources of the Data Center in a highly granular manner which helps them to identify the location where the assets (such as power, space, cooling and connectivity) exist and where they are being used. Loss of resources occur within a facility like Data Center if there is difficulty in locating and identifying resources. Stranded capacity or vertical white space are terms used to describe such situations. Often in such cases originally designed resources such as UPS power, rack space or cooling devices get “fragmented” meaning that they insufficient in areas as per the need of the network device/equipment.

Let’s take an example, a server requires 500 KWh power and requires 3U space for its set up but the two available empty spaces in cabinets provide 400kWh power with 5U space or 700KWh power with 2U space. Now none of the two available spaces provide the best fit rack. This is a wasteful way of handling resources and is referred to as stranded capacity.

DCIM could prevent the creation of stranded capacity or white space through Asset Management and Capacity Planning.

Intervention of DCIM to eliminate white space/ stranded capacity:

Asset Management:

- Auto-discovers all intelligent assets, including facility devices like UPS, PACs, PDUs, Sensors that support SNMP and those connected through BMS

- Captures inventory of the assets using SNMP

- Maps all static attributes of the assets from built-in OEM library, called Manufacturer Repository

- Tracks unrecorded changes in asset configuration to keep the asset inventory consistent and updated all the time

- Maps critical relationships and dependencies among assets. This mapping also depicted on the Power Chain

- Provides Lifecycle Management and Preventive Maintenance Schedules

- Provides Workflow-based system to perform Move-Add-Change operations

- Floor & Rack elevation through 2D & 3D Data Center Layout & Visualization

- 3D Elevation Modelling of Racks and Cages: Improves staff productivity through multi-filter search capabilities, up-to-date asset inventory of all Facilities & IT devices and real-time status visually displayed on DC layout.

Capacity Planning

- What-if analysis on Power, Space & Cooling. Resource Provisioning

- Inventory Management: Base-lining of data center resources being utilized and what capacity is available

- Freeing-up of stranded power, floor and rack space, cooling and IT capacity in the data center

- Forecasting future capacity requirement

- Validation of projected capacity requirements through ‘What-if’ analysis, simulations and modelling

- Identifying best place to provision new asset based on available capacities

- For Colo data centers, workflow-based provisioning based on customer orders

- Auto Provisioning (identifying the best racks in the data center for new device provisioning)

GFS Crane DCIM Capacity Planning enables optimal rack allocations, determination of upstream power requirements based on additional rack loads and cooling requirements based on thermal profiles. Better rack & floor space utilization leads to higher usage of existing capacities and deferring new builds or leasing new facilities.

A relevant read on Asset Relationship & Capacity Planning:

Asset relationship in dcim Capacity planning in data center

Why is 3D Visualization of Data Center important in DCIM?

The human brain is able to respond much faster to a visual description in 3 dimensions rather than a string of messages in text. With the objective of equipping data center managers in making quick, yet fully informed decisions, DCIM developers saw the practical advantage of building 2D and 3D visual tools for effective Data Center Infra Management. Today, we have DCIMs with fully-integrated, browser-based 3D Modelling and management environments for Data centers. Built well, the tool is fast, reliable and also becomes the base for enhanced data center planning and analytics.

Whether for day-to-day Data center monitoring activities or for Asset management, the 3D view has become an indispensable tool for the Data center team.

3D View for effective Data Center Monitoring:

A 3-dimensional view of the data center on your browser, allows you to virtually walk through the Data center, even when you are miles away from the actual site. Zoom in, zoom out, Rotate and examine an interactive, isometric view of your data center.

As one virtually walks through the racks, the user is allowed to ‘see’ live, the rack’s vital statistics such as temperatures, humidity, power loads on each Rack. If the key metrics on any rack, should breach pre-set threshold values, a visual alert notification, in the form of a change in colour code for the affected rack or u-space alerts the user and helps him quickly isolate the area. This visual, accurately directs emergency response teams to the exact Row/Rack or u-space, to investigate and resolve the issue in its incipient stage, before the situation builds up into a major breakdown or failure, thus enhancing uptime and Data center resilience.

For more on the subject please click on the link below:

Why dcim driven 3d visualization of the data center is important Data center layout modelling and visualization